BERLIN-- January 25, 2023 -- Graforce, Germany’s leading provider of zero carbon hydrogen plants, and Kawasaki Gas Turbine Europe GmbH (Kawasaki), a European gas turbine and heat-power cogeneration business, are cooperating for zero-emission heat and power generation. The joint innovative plant concept combines Graforce's methane electrolysis technology (plasmalysis) with hydrogen turbines from Kawasaki. First customer projects for this zero carbon heat and power solution are in the works.

“Our joint zero-emission plant is a breakthrough for the decarbonization of both, fossil fuels and manufacturing industries”, explains Dr. Jens Hanke, CTO of Graforce. “This technology generates CO2-free high-temperature heat via hydrogen, the carbon black is used as a raw material in production, and - best of all, the process is self-sufficient and does not need further electricity after having been started. This in turn relieves the strain on power grids.”

Decarbonization of industrial processes

The new plant solution generates hydrogen from biomethane, natural gas, LNG or LPG by methane electrolysis technology. The hydrocarbons will remain the initial source, but instead of being burnt, a high frequency plasma splits the hydrocarbons into CO2-free hydrogen and carbon black.

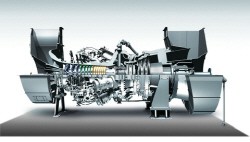

The hydrogen is converted to electricity in Kawasaki's hydrogen gas turbine and reused for hydrogen production in the plasma electrolyzer. The ultra-high temperature CO2-free exhaust gas from the hydrogen gas turbine can be used in production processes in various industries. Companies that previously generated high-temperature heat with natural gas can significantly increase their overall efficiency while reducing their gas and especially electricity costs.

Carbon black is used as a synthetic raw material for industrial production. This way, CO2 can be sequestered long-term in steel, cement or for soil enhancement. For industries which require both high temperatures and large quantities of carbon black for production this process pays off twice - in terms of climate protection and cost-effectiveness.

Beyond industry, this hydrogen-based heat-power cogeneration plant can be used for CO2-free heating in surrounding urban areas.

Both technologies were awarded with the Innovation Award of the German Gas Industry, in 2020 and 2022.